|

9th June 2021

In the last VR-related blog post, I pointed to the LEO I half adder that is in store at the Birmingham Museum. The half adder was critical to the function of the LEO I as a computer and we would find this same function in a modern computer. So, why do the electronics of LEO’s time look so different to the electronics we have today? Was it simply that it was bigger?

I can hear the response, because today we have digital electronics! But what does that mean?

We would like to include the half adder as part of the VR version of the LEO I installation. Modelling these 1950s electronics was certainly a challenge and of course included a need to understand the components found at that time, just a little better.

The LEO engineers were building a computer-based upon the work of Maurice Wilkes and his team at the University of Cambridge with EDSAC. Although their perception of what a computer might ultimately do is nowhere near what we have today, they knew that they were building a machine that was well defined and must work in principle as a ‘digital’ device. This means that parts of the machine will offer logical functions operating on binary inputs and outputs. The machine must function according to the laws of boolean algebra. It will operate as a digital (binary) device and any results it produces must be an outcome of the logic of a series of machine instructions, with no room for any error or variation.

During the 1950s if instead, they decided to build radio, then they would be constructing a device whose function is not digital but analogue and therefore in theory no two radios were ever the same. One might be slightly quieter than another, perhaps barely perceptible but a difference. Another might need a small adjustment on the tuning dial to better receive a radio transmission, again a difference and of no real consequence to the user. Building an analogue device in an analogue world, results in variation but usually with little or no consequence. With a computer, we are presented with a very different challenge.

In a digital device like a computer, a variation in the function of one of its parts can change the way a logical function within the system operates and ultimately unintentionally somewhere a 1 becomes a 0 or a 0 becomes a 1. In the end, the value of the output changes and that (in a digital world) will lead to an error which for the applications that the computers were to be used for, would be unacceptable.

For Lyons, using a digital computer to perform millions of complex business calculations required one hundred per cent accuracy. It had to work perfectly and consistently. Errors would threaten the business or the customers and that would never work.

Lyons were famous for their cakes! They would try very hard to ensure that the cakes were made to the maximum consistency. The cakes were real-world items made in the real world and therefore made in an analogue way. A slight variation was tolerated and almost certainly was not perceivable by the consumer. A small ‘error’ was not significant but in the world of digital electronics, a small error might change the course of a set of instructions or alter the value of a piece of data significantly. When a 1 becomes a 0, what appears to be a small change can result in very significant outcomes with disastrous results.

The LEO engineers were surrounded by analogue electronics. Electronic components that were invented and had been used to service the needs of analogue devices. Most of the engineers had a great experience working with electronics in an analogue way, in areas such as RADAR and radio, associated often with their wartime service. How could these analogue electronic components be assembled in such a configuration as to make them ‘act’ in a digital way?

Chief amongst the critical components to be found in electronics during the 1940s and 50s, was the thermionic valve.

Popular in almost every piece of electronics at that time, there were many different types of valve (the Americans called them ‘tubes’). They varied in size and function and many manufacturers were developing smaller and improved versions all the time. LEO was to be built using units of electronics that heavily depended upon the thermionic valve. Thousands of these glass-encased, vacuum filled, curious pieces of hot technology would enable LEO to perform its logical functions and behave like a digital device.

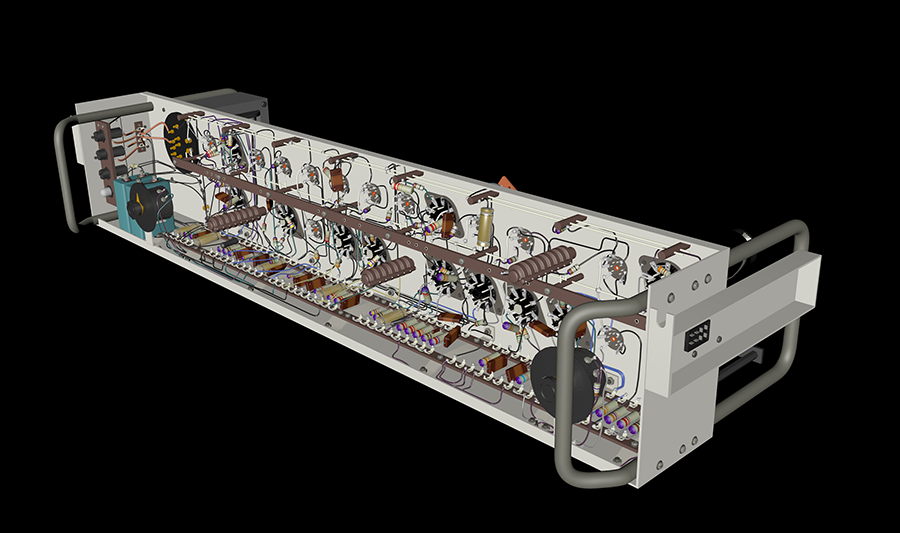

LEO’s 21 racks each held 12 units of electronics. Each unit had a specific function and could be easily swapped for another unit if needed. The half adder was such a unit and typical of one of the functions that the units needed to serve.

Typically 20 - 25 valves per unit meant that LEO used over 6,000 thermionic valves and of mainly six different types.

The valve was a device that, put simply, enabled the control of the flow of electrical current. Once controlled it was possible with other supporting components, to manipulate the valve to perform the functions needed for the device being used. LEO’s electronic units would use groups of valves to emulate the function of logic gates, critical to the computer’s needs.

The half adder used 23 valves of 5 different types. Each had a code to identify its function and these were;

7 x ECC33

8 x D77

4 x 6AL5 (3)

3 x VR65

1 x EL33

The valves were made by companies such as Mullard.

Modelling the valves for the half adder in the VR version of LEO I, was challenging and I hope we have achieved enough accuracy to give the virtual visitor a good idea of what a valve looked like and how it supported the LEO machine.

If you would like to know more about the thermionic valve, there is an excellent online resource called The Valve Museum. The types of valve used for LEO I can be found in the museum.

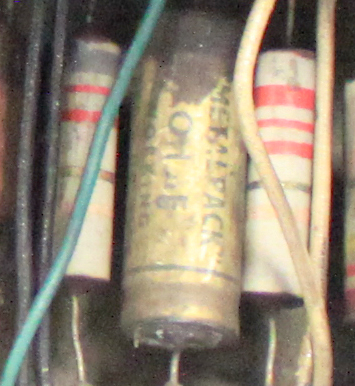

What other components were found supporting the valves? Each valve was plugged into a special ‘valve holder’ and that enabled several electrical connections to be made to the internal parts of the valve. Electricity supplied to the valve needed to be passed through other electronic components to ensure that it was at the correct level etc. The most common of these components were resistors and capacitors.

The resistor as the name suggests was a small device that resisted the flow of electrical current and had hundreds of different values that determined how much resistance it provided. The different types of resistor were indicated by coloured bands acting as codes.

Capacitors acted to resist direct current. Also over very short periods of time, the capacitor can store and release electrical energy.

Other components discovered during the examination of the half adder include; a transformer, mains dropper, potentiometer, fuses, wires etc.

The half adder has hundreds of components supporting its groups of valves and therefore LEO in total was constructed using tens of thousands of these ‘passive’ electronic components.

Look carefully at the underneath of the LEO I half adder. Although organised in construction, it is clear that each basic component has been added to the circuit by human hand and individually. This method of construction was time-consuming and subject to error either in making a mistake with where a connection is to be made or not making a ‘soldered’ connection of good enough quality to enable the electrical energy to flow consistently over time. Curiously this is reflected in the virtual version of the half adder where each virtual component had to be ‘placed’ to best represent the real device.

Every electronic component used had a value that in fact was a range of acceptable values (tolerance). Manufacturing techniques and cost could limit the ability to predict where in a range, the values would settle for one device compared to another. During use these component values would often ‘drift’, caused by factors such as age, temperature and even what other component was close by. The cumulative drift of a complex group of electronics would present enormous challenges to engineers to maintain the digital function of the unit in question.

Despite best efforts the ‘digital’ function of the unit of electronics was dependent upon the individual nature of the analogue components and their ‘real world’ construction. This inevitably would lead to unintended variation between two units and potential errors or failures that could be quite difficult to diagnose, identify and fix. This made the idea of the ‘standard’ unit difficult to realise as each unit was the outcome of hundreds of analogue influences.

Ultimately the thermionic valve will be replaced with the transistor and this has enabled the construction of units of electronics to be automated. Hugely increased component quality and the manufacture of units by machine, not by hand, has resulted in vastly improved consistency and reliability. Components have now been integrated into packages that are manufactured at sizes too small for the human eye and this has led us to the world of digital electronics that we have today.

We must remember however, that deep inside this digital device very tiny electronic components are grouped together to ‘perform’ digital functions. But they themselves are still analogue devices acting their part to mimic a digital function such as a logic gate in a computer.

The digital world is one that obeys the laws of logic - boolean logic. It really only exists in the minds of mathematicians because we live in an analogue world. We have become very good at grouping analogue devices together to mimic a digital function with almost complete reliability and consistency. The task for the LEO engineers was to construct a machine in which a group of components could reliably act their digital parts. But when things went wrong, how could the LEO engineers avoid spending all their time tracking down the analogue faults that could make this digital dream unachievable? Building the digital out of the analogue was tough enough, keeping it there was a whole other story!

Posted by: Chris Monk

|